Design, installation and maintenance of building management systems for industrial facilities, office buildings and institutions since 1992.

We provide the design, installation and maintenance of building automation systems for industrial facilities, office buildings and institutions.

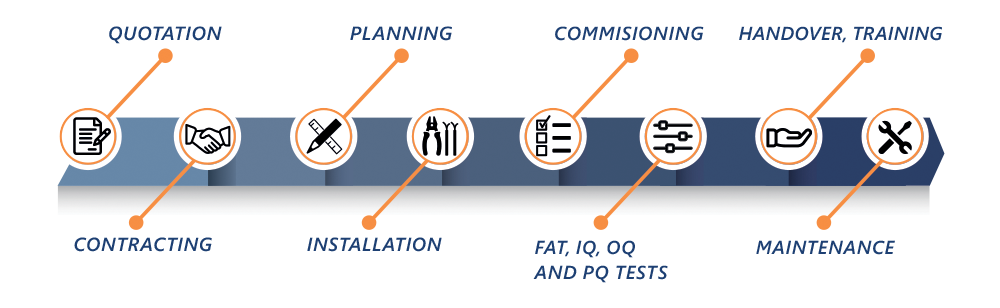

According to the principles of our company, and focusing on fair and responsible business behaviour, we strive to perform quality work from quotation to finalising the implementation.

The building automation systems we install and commission guarantee the long term humidity meeting the given specifications, the temperature and air quality required for the manufacturing processes, storage, office work and for other buildings with special functions.

QUOTATION

For the building automation quotation requests, our technical preparative team, depending on the details and information received, will do its best to give a quotation within 1 week for the implementation of primarily SIEMENS building management systems.

In our industrial sector, there are no similar quotations, each project is different, requiring unique building automation solutions.

Nevertheless, we need the following information to be able to prepare the quotation as quickly as possible, with as many technical details as possible:

We need to know the deployment plan for the building automation system, containing:

- The budget plan

- The technical description

- A dimensional drawing, indicating the scale

- A scheme drawing

- A wiring diagram

In the lack of this information, we can only prepare our quotation with an extended deadline.

During an on-site visit, considering the needs and possible extra requests of the Customer, we try to clarify and specify the available information to be able to implement a building management system that is really cost-effective and operational in the long run.

This joint work is always followed by concluding a contract.

INSTALLATION

Since our building automation installation projects are managed by experienced project managers and installation managers, we can serve our Customers in an efficient, quick and flexible manner.

Before commencing installation works, our installation branch manager and our technical preparative team drafting the quotation discuss the details of the project, its technical and economical requirements, and the possible pitfalls. A project manager and a technical project team suited for the project size are appointed to coordinate the entire deployment process.

The project manager is responsible for discussions with the Customer. They choose the most suitable subcontractors and suppliers required for each process. We place great emphasis on following labour safety requirements and on properly maintaining the construction log. Our Technical Managers in Charge, together with the construction manager and installation manager, direct the given project by on-site cooperation. Our assembly procedures are performed on the basis of our own Technological Instructions, broken down to sub-tasks, meeting the deadlines agreed upon with the Customer and/or Consignor.

After assembly, commissioning is performed by our software engineers and commissioning team.

They document the commissioning process in a precise, highly professional way, filling in an installation form, writing heavy current and automatics commissioning reports, and the data point list for the given project. They test the operation of the BMS system according to the Customer’s needs. A test operation is performed for the duration required by the Customer. Thanks to our extended pharmaceutical BMS experience, (upon request) we conduct FAT, IQ, OQ and PQ tests as well, and we also create the documentation required for these.

After commissioning the building management system, at the end of the project, a complete acceptance documentation is handed over to the Customer both as a hard copy and in electronic form.

We organise a training on the usage of the implemented building automation system for the operator and maintenance teams, which is also documented in reports.

During our building automation deployment projects, we aim to create stable and reliable BMS systems, but we also try to troubleshoot possible failures as soon as possible, within the guaranteed period.

MAINTENANCE

During the long years of operation, the building automation system needs inspection and maintenance in order to ensure its functionality. By regular maintenance of the building management system and by preventing the related damages, malfunctions, partial or total shutdowns or the resulting production or financial losses can be avoided.

By regular maintenance, operational costs can be significantly reduced in the long run.

Our maintenance staff, based on its professional experience, is able to perform specialist maintenance tasks of the building management system, instantly replace the required parts, and provide advice on modifications and changes, scaling up, and extension of the system made necessary during operation. They use company vehicles, therefore, can arrive at the site and start the troubleshooting process in a short time.

Our unique service is heat camera based diagnostics, which enables us to provide an even more accurate picture of the building automation system, abnormal heat emission, electric devices, and the status of electric cabling and transformers. We can perform the heat camera assessment during operation, in industrial conditions. This makes it possible to schedule and optimise the time and costs of maintenance and repairs, helping prevent failures.